1. Diesel concrete mixer

1) Specifications

Model | JZR350 | JZR500 |

Hopper Lifting Model | Hydraulic/Steel wire rope | Hydraulic Tipping Hopper/Steel wire rope |

Production Capacity | 10m3/h | 15m3/h |

Power Source | Diesel Engine | Diesel Engine |

Charging Volume | 560 L | 750 L |

Discharge Volume | 350 L | 500L |

Dimension | 3250*2240*3200 mm | 3750*2240*3800 mm |

Weight | 1610 kg | 2050KG |

2) Pictures

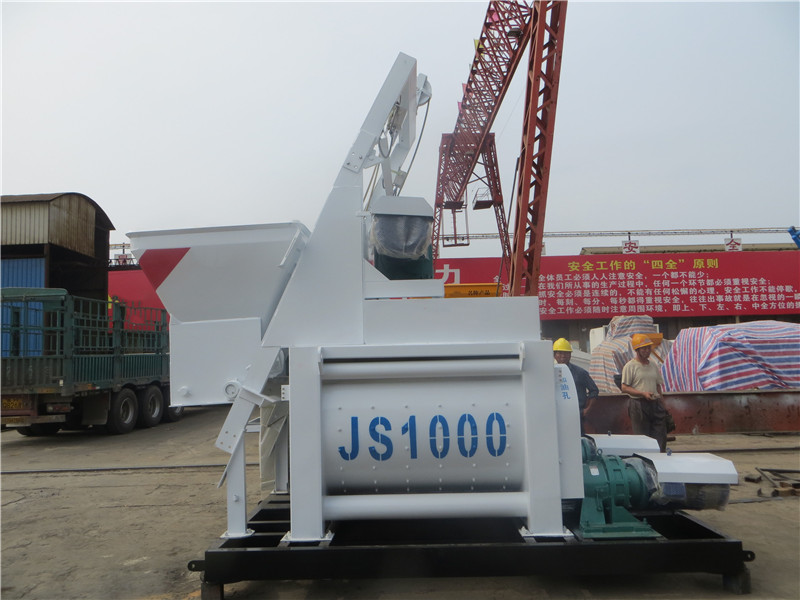

2. Twin-shaft concrete mixer

1) Specifications

Model | JS500 | JS750 | JS1000 | JS1500 | JS2000 | JS3000 | JS4000 |

Charging Capacity | 800L | 1200L | 1600L | 2400L | 3200L | 4800L | 6000L |

Discharging Capacity | 500L | 750L | 1000L | 1500L | 2000L | 3000L | 4000L |

Production capacity | 25m3/h | 35m3/h | 60m3/h | 90m3/h | 120m3/h | 180m3/h | 240m3/h |

Max. Agg. size | 40/50mm | 60/80mm | |||||

Overall Weight | 4000kg | 5500kg | 9700kg | 11130kg | 13500kg | 15000kg | 16000kg |

2) Pictures

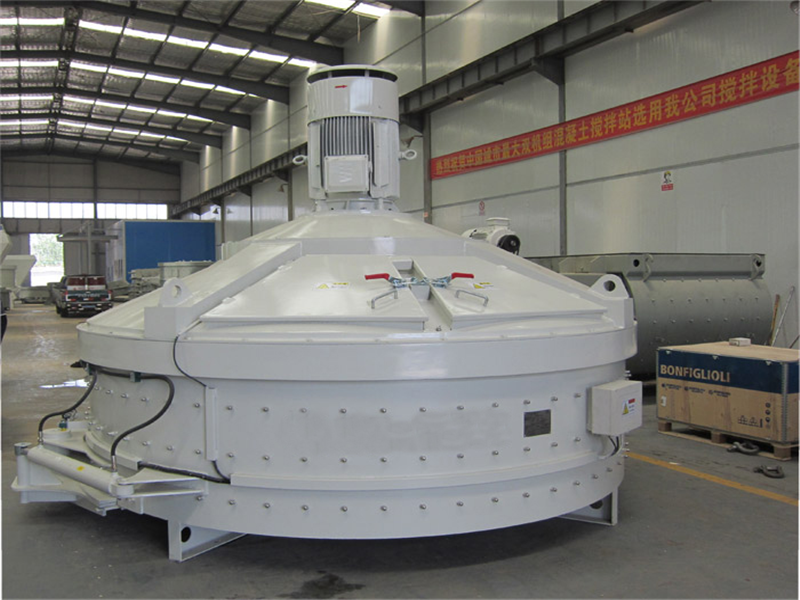

3. Planetary concrete mixer

1) Specifications

Model | CMP500 | CMP750 | CMP1000 | CMP1500 | CMP2000 |

Feeding capacity (L) | 750 | 1125 | 1500 | 2250 | 3000 |

Discharging capacity (L) | 500 | 750 | 1000 | 1500 | 2000 |

Mixing motor power (Kw) | 18.5 | 30 | 37 | 55 | 75 |

Production capacity | 25m3/h | 35m3/h | 60m3/h | 90m3/h | 120m3/h |

Weight (Kg) | 2400 | 3900 | 6200 | 7700 | 9500 |

2) Pictures

4. Drum concrete mixer

1) Specifications

Model | JZC250 | JZC350 | JZC500 | JZC750 |

Feeding capacity (L) | 320 | 560 | 800 | 1200 |

Discharging capacity (L) | 250 | 350 | 500 | 750 |

Mixing motor power (KW) | 5.5 | 5.5 | 15 | 15 |

Production Capacity (m3/h) | 6-8 | 10-14 | 18-20 | 20-30 |

Weight (KG) | 1300 | 1610 | 3200 | 4350 |

2) Pictures

Advantages:

A concrete mixer is a machine used in construction to blend cement, sand, gravel, and water to form concrete. These machines come in various sizes and designs, from portable mixers suitable for small-scale projects to large stationary mixers for industrial applications.

Mixing: The primary function of a concrete mixer is to blend cement, sand, gravel, and water to form a homogeneous mixture of concrete.

Batching: Concrete mixers allow precise measurement and batching of ingredients, ensuring consistency in the quality of the concrete produced.

Transportation: Portable concrete mixers can be moved to different locations on construction sites, allowing flexibility in mixing concrete where it is needed.

Time-saving: Using a concrete mixer can significantly reduce the time and labor required for manual mixing of concrete ingredients, especially for large construction projects.

Versatility: Concrete mixers can be used to produce different types of concrete, such as ready-mix concrete, precast concrete, or specialty concrete mixes.

Uniformity: Properly operated concrete mixers ensure uniform mixing of ingredients, resulting in consistent strength and durability of the concrete produced.

Overall, concrete mixers are essential machines in construction projects, providing efficient and reliable mixing of concrete ingredients to meet the requirements of various construction applications.As a professional Concrete Mixer Supplier, we can provide high quality China Concrete Mixer, please contact us!