As a manufacturer of concrete batching plant with 20-year experience, we have mobile concrete batching plant with the capacity from 20m3/h to 100 m3/h.

A mobile concrete batching plant is a specialized type of equipment used in construction projects where concrete needs to be produced on-site.

Mobility: Designed for easy transportation between construction sites, a mobile concrete batching plant is mounted on trailers or wheels, allowing it to be quickly relocated as needed.

Compact Design: Typically compact in size compared to stationary plants, making it suitable for projects with limited space or frequent site changes.

Versatility: Capable of producing various types of concrete mixes including ready-mix concrete, precast concrete, and specialty mixes, meeting specific project requirements.

Environmentally Friendly: Often designed with features that reduce dust emissions and noise levels, complying with environmental regulations and site requirements.

Cost-Effective: Offers cost savings by eliminating the need for transporting ready-mix concrete from distant plants, reducing logistics costs and project delays.

Advantages of Mobile Concrete Plants:

Flexibility: Easy to move from one location to another, ideal for projects requiring frequent relocation.

Quick Setup: Minimal assembly time, allowing rapid deployment and operation.

Compact Size: Designed to fit into smaller spaces, making them suitable for urban and confined construction sites.

Cost-Effective: Lower transportation costs and reduced setup time compared to stationary plants.

The construction industry has increasingly turned to mobile concrete plants for their flexibility and efficiency. These versatile facilities, known as mobile concrete plant, offer contractors a way to produce high-quality concrete directly at the project site or in close proximity. The ability of a batching plant mobile setup to be relocated quickly makes it an invaluable asset for projects spread over large areas or in remote locations. With mobile concrete batching plants, operators can significantly reduce transportation costs and time, ensuring that fresh concrete is always available when and where it's needed. The compact design of these units allows them to fit into tight spaces, making them suitable for urban construction sites as well.

For those looking for temporary solutions without sacrificing quality, portable concrete plants provide a practical alternative. A mobile concrete batch plant can be set up and operational within a short timeframe, adapting to various project requirements. These concrete batching plant mobile systems are engineered to deliver consistent performance even under challenging conditions, thus supporting uninterrupted workflow. The mobility of these plants means they can serve multiple projects sequentially, maximizing the return on investment. Moreover, the ease of assembly and disassembly of portable concrete plants ensures minimal disruption to ongoing operations, allowing for smooth transitions between different job sites.

Innovations in technology have led to the development of advanced mobile mixing plants that integrate seamlessly into construction processes. These mobile concrete plants are designed to optimize production rates while maintaining stringent quality control standards. Operators benefit from the enhanced efficiency and reliability that comes with using a mobile concrete batching plant, which can handle everything from small-scale residential projects to large infrastructure developments. The adaptability of mobile mixing plants to different environments and materials further underscores their value in today's dynamic construction landscape. By choosing a concrete batching plant mobile solution, companies can achieve greater operational flexibility and respond more effectively to changing market demands.

Why choose a mobile concrete batching plant?

Quick and easy installation (1-2 days)

Cost-effective transportation

Quick and easy relocation

Minimum foundation cost

Some other outstanding features of our mobile series plants include: fully installed and ready for use in 8 hours; all components are in trusses, universal configuration of auxiliary silos and conveyors can adapt to any site, and the entire plant is pre-wired for air and water. After manufacturing, each plant is factory tested, which helps to achieve trouble-free start-up and operation. Whether you want the highest output, the largest total storage capacity, or a plant that can grow with your business, Shengmao is your solution.

Currently, we have three types of mobile concrete batching plant: YHZM series mobile concrete batching plant; NYHZS series mobile concrete batching plant and YHZS series mobile concrete batching plant.

YHZM series of mobile concrete batching plant

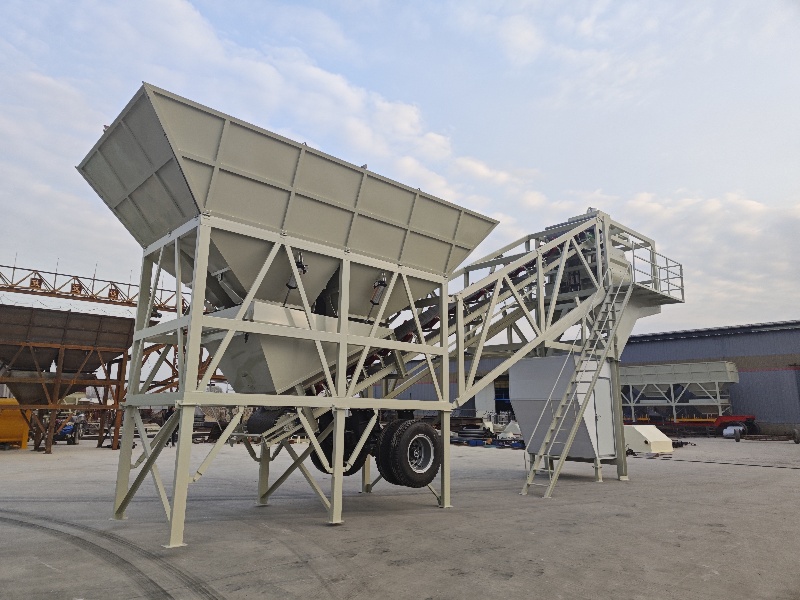

1. Pictures of YHZM series of Mobile Concrete Plant

2. Specifications of YHZM series of mobile concrete plant

| Model | YHZM20 | YHZM30 | YHZM60 | YHZM100 |

| Production capacity (m3/h) | 20 | 30 | 60 | 100 |

| Concrete mixer | JZM500 | JZM750 | JZM1500 | JZM2000 |

| Aggregate feeding mode | Belt conveyor | Belt conveyor | Belt conveyor | Belt conveyor |

| Aggregate size(mm) | 80/60 | 80/60 | 80/60 | 80/60 |

| Discharging height(m) | 1.5 | 1.5 | 1.5 | 1.5 |

| Aggregate weighing accuracy (%) | ±2 | ±2 | ±2 | ±2 |

| Cement weighing accuracy (%) | ±1 | ±1 | ±1 | ±1 |

| Water weighing accuracy (%) | ±1 | ±1 | ±1 | ±1 |

| Additive weighing accuracy (%) | ±1 | ±1 | ±1 | ±1 |

| Control system | Panel | Computer | Computer | Computer |

| Total power (kw) | 42 | 46 | 67 | 77.5 |

| Total weight) | 12 | 13 | 14.5 | 26 |

3. Features of YHZM series of mobile concrete batching plant:

1) It's no need to make concrete foundation, we can save much time, cost and labour work;

2) Easy to install. We usually need 3 days to finish the installation;

3) It is cost-saving. Compared with other mobile concrete batching plant, YHZM type is much cheaper;

4) The mixer is drum type concrete mixer;

5) The cement silo is horizontal type, no need foundation;

6) The concrete discharging height is 1m; we need to use a belt conveyor or we can make a slope to increase the height to enable concrete transit mixer to collect concrete.

NYHZS series of mobile concrete batching plant

1. Pictures of NYHZS series of mobile concrete batching plant

Know more about mobile concrete batching plant:

Different Types of Concrete Mixing Plants

Why choose mobile batching plant?

Mobile Concrete Batching Plant Processing Technology

2. Specifications of NYHZS series of mobile concrete batching plant

| Model | NYHZS25 | NYHZS35 | NHZS50/60 | NYHZS75/90 |

| Theoretical production capacity (m3/h) | 25 | 35 | 50 | 75 |

| Concrete mixer | JS500 | JS750 | JS1000 | JS1500 |

| Aggregate feeding mode | Belt conveyor | Belt conveyor | Belt conveyor | Belt conveyor |

| Aggregate size(mm) | 80/60 | 80/60 | 80/60 | 80/60 |

| Discharging height(m) | 4.1 | 4.1 | 4.1 | 4.1 |

| Aggregate weighing accuracy (%) | ±2% | ±2% | ±2% | ±2% |

| Cement weighing accuracy (%) | ±1% | ±1% | ±1% | ±1% |

| Water weighing accuracy (%) | ±1% | ±1% | ±1% | ±1% |

| Additive weighing accuracy (%) | ±1% | ±1% | ±1% | ±1% |

| Total weight (T) | 12 | 20 | 21 | 24 |

| Total power (T) | 60 | 72 | 72 | 87 |

| Control system | Computer | Computer | Computer | Computer |

3. Features of NYHZS series of mobile concrete batching plant:

1) It's no need to make concrete founcation, easy to install and move to other job sites;

2) the concrete mixer can be twin-shaft mixer, pan mixer and planetary mixer;

3) the cement silo is horizontal type, no need foundation;

4) the concrete discharging height is 1m; we need to use a belt conveyor or make a slope to increase the height to enable concrete transit mixer to collect concrete.

YHZS series of mobile concrete batching plant

1. Pictures of YHZS series of mobile concrete batching plant:

2. Specifications of YHZS series of mobile concrete batching plant

| Model | YHZS25 | YHZS35 | YHZS50/60 | YHZS75/90 |

| Production capacity (m3/h) | 25 | 35 | 50 | 75 |

| Concrete mixer | JS500 | JS750 | JS1000 | JS1500 |

| Aggregate feeding mode | Belt conveyor | Belt conveyor | Belt conveyor | Belt conveyor |

| Aggregate size(mm) | 80/60 | 80/60 | 80/60 | 80/60 |

| Discharging height(m) | 4.1 | 4.1 | 4.1 | 4.1 |

| Aggregate weighing accuracy (%) | ±2% | ±2% | ±2% | ±2% |

| Cement weighing accuracy (%) | ±1% | ±1% | ±1% | ±1% |

| Water weighing accuracy (%) | ±1% | ±1% | ±1% | ±1% |

| Additive weighing accuracy (%) | ±1% | ±1% | ±1% | ±1% |

| Total weight (T) | 14 | 22 | 26 | 29 |

| Total power(kw) | 60 | 72 | 92 | 102 |

| Control system | Panel | Computer | Computer | Computer |

3. Features of YHZS series of mobile concrete batching plant:

1) we need to make concrete foundation;

2) the concrete mixer can be twin-shaft mixer, pan mixer and planetary mixer;

3) the cement silo is vertical type, we need to make big concrete foundation;

4) the concrete discharging height is 4.1m which is easy for concrete transt mixer to collect concrete.

4. Introduction video of YHZS series of mobile concrete batching plant:

How do we increase the discharging height for YHZM and NYHZS series of mobile concrete batching plant?

1. Using belt conveyor

2. Making a slope

Vedio of our mobile concrete batching plant

International cases of our mobile concrete batching plant

1. YHZM20 mobile concrete batching plant in Srilanka

2. YHZM60 Mobile concrete batching plant in Philippines

3. YHZM60 mobile concrete batching plant in Mozambique

4. YHZS50 mobile concrete batching plant to Central America.

Welcome to contact us for details and quotations.