About Mobile Asphalt Plant

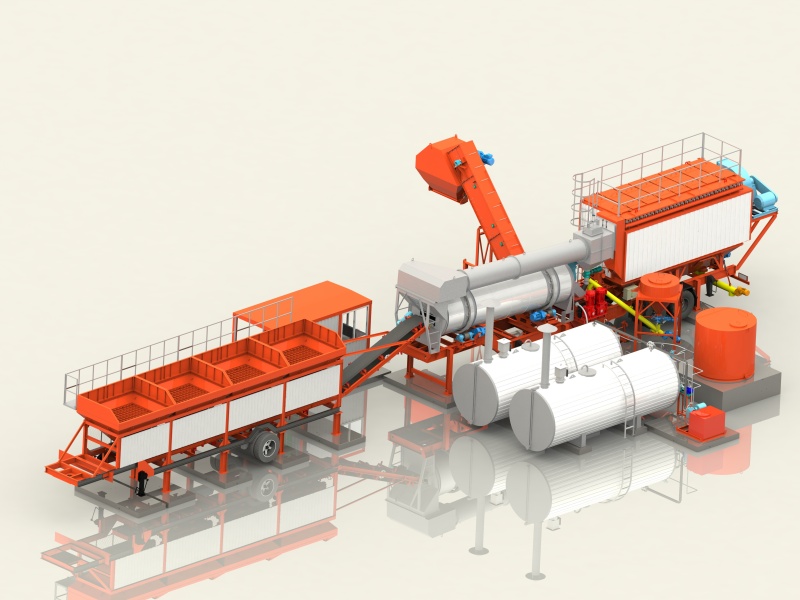

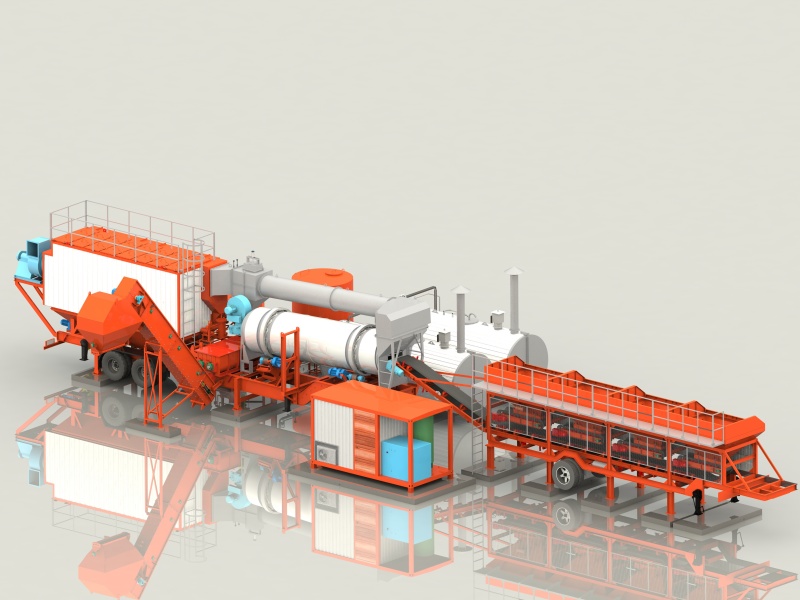

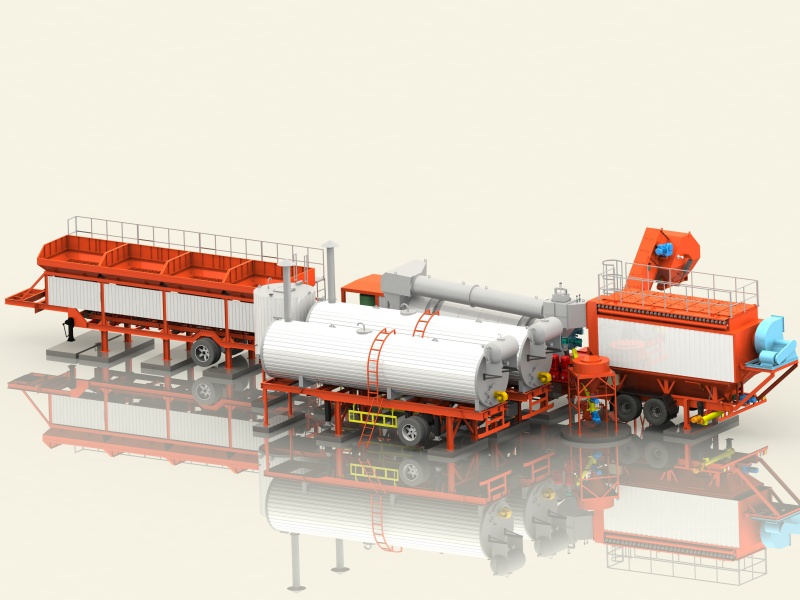

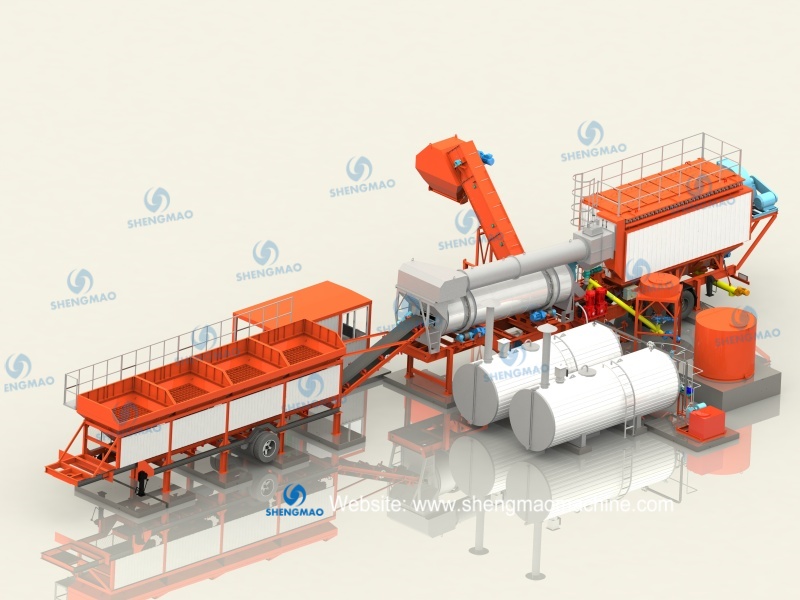

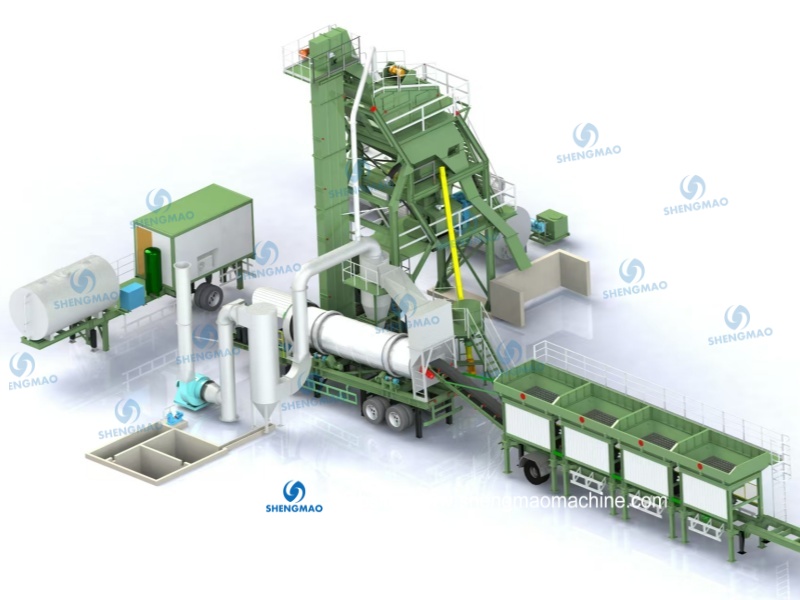

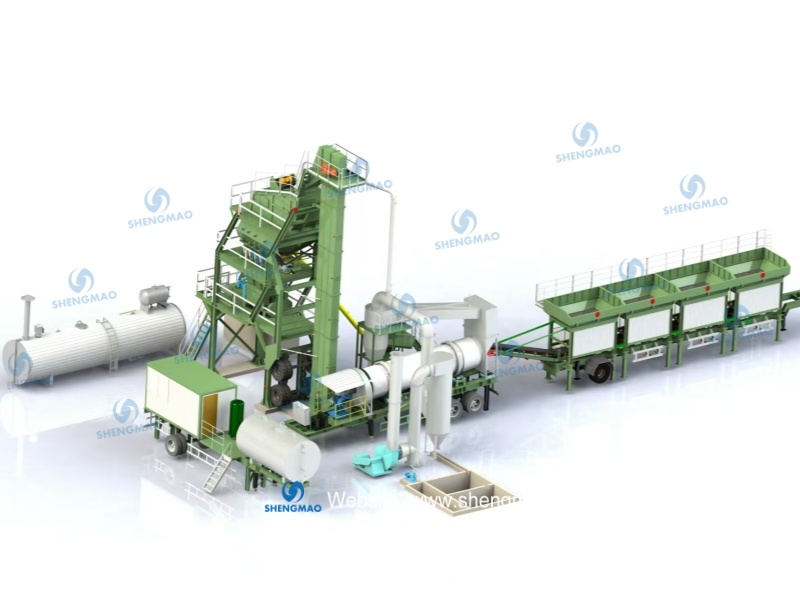

Nowadays, there are more and more small and medium-sized road projects for which we need to frequently change the location of asphalt mixing plant. In order to meet the demands of our clients, we developed different types of mobile asphalt: drum type (MDHB series); compulsory type (QLB series); road repairing type (QLZ type).

In the field of road construction and maintenance, the selection of asphalt mixing equipment is crucial to ensure the quality and efficiency of the project. A widely used equipment is the Asphalt Drum Mix Plant (asphalt drum mix plant), which can efficiently produce uniform quality asphalt mixture through a continuous mixing process, which is very suitable for large-scale road paving projects.

At the same time, mobile asphalt mixing plants are popular because of their high flexibility. This type of equipment can quickly move the construction site to adapt to the needs of different locations, greatly improving the convenience and efficiency of construction. There are many mobile asphalt mixing plants for sale on the market, which provides great convenience for contractors who need to change the work site frequently.

In particular, the asphalt drum plant is also a type of continuous mixing technology. It achieves an efficient production process by adding all raw materials into a rotating drum for heating and mixing at one time. This type of mixing plant can save fuel and reduce emissions while maintaining efficient production, which is beneficial to environmental protection.

In short, whether it is a fixed asphalt drum mix plant, a flexible and versatile mobile asphalt plant, or an environmentally friendly and efficient asphalt drum plant, they all provide strong support for modern road construction. For those who are looking for mobile solutions, the mobile asphalt plant for sale available on the market undoubtedly provides an economical and practical choice. Please contact us to learn more!

Advantages of Mobile Asphalt Plants:

Flexibility: Easy to move from one location to another, ideal for projects requiring frequent relocation.

Quick Setup: Minimal assembly time, allowing rapid deployment and operation.

Compact Size: Designed to fit into smaller spaces, making them suitable for urban and confined construction sites.

Cost-Effective: Lower transportation costs and reduced setup time compared to stationary plants.

High Productivity: Capable of producing a significant volume of asphalt per hour, depending on the model.

For drum type, we use drying drum to dry aggregates and mix them with bitumen. No ore powder will be used. It is usually used for small and low-level road construction. Capacity available: 20t/h to 100t/h.

For compulsory type, there is mixer to mix all the materials like stones, ore powder and bitumen. All materials will be weighed before being discharged into mixer to ensure the accuracy of the asphalt formula. Usually, it is used for small and medium-sized road construction. Capacity available: 10t/h to 80t/h.

For road repairing type, we reuse the asphalt on broken road and repair the road. It is widely used for all kinds of road repairing. Capacity available: 3t/h and 6t/h.

Are you interested in learning more about mobile asphalt plant and how they can benefit you? Contact us today to secure an expert consultation!

Specification and Pictures of Drum Type Mobile Asphalt Plant

MDHB20 | MDHB40 | MDHB60 | MDHB80 | MDHB100 | |

Production Capacity (T/h) | 20 | 40 | 60 | 80 | 100 |

Mixing Type | Continuous | Continuous | Continuous | Continuous | Continuous |

Dust Remove Effect (mg/Nm3) | ≤100 | ≤100 | ≤100 | ≤100 | ≤100 |

Fuel Consumption (kg/t) (Oil) | 5.5-7 | 5.5-7 | 5.5-7 | 5.5-7 | 5.5-7 |

Fuel Consumption (kg/t) (Coal) | 10-13 | 10-13 | 10-13 | 10-13 | 10-13 |

Aggregate Weighing Accuracy(%) | ±1.5 | ±1.5 | ±1.5 | ±1.5 | ±1.5 |

Bitumen Weighing Accuracy(%) | ±1 | ±1 | ±1 | ±1 | ±1 |

Total Power (kw) | 50 | 75 | 128 | 165 | 200 |

Specification and Pictures of YLB series Compulsory Type Mobile Asphalt Plant

Model | YLB700 | YLB1000 | YLB1200 | YLB1500 | YLB2000 |

Production Capacity (T/h) | 60 | 80 | 100 | 120 | 160 |

Mixer Capacity Per Batch(kg) | 750 | 1000 | 1200 | 1500 | 2000 |

Cycle Time Per Batch(s) | 45 | 45 | 45 | 45 | 45 |

Dust Remove Effect (mg/Nm3) | ≤20 | ≤20 | ≤20 | ≤20 | ≤20 |

Fuel Consumption (kg/t) (Oil) | 5.5-7 | 5.5-7 | 5.5-7 | 5.5-7 | 5.5-7 |

Fuel Consumption (kg/t) (Coal) | 10 | 10 | 10 | 10 | 10 |

Aggregate Weighing Accuracy (%) | ±0.5 | ±0.5 | ±0.5 | ±0.5 | ±0.5 |

Filler Weighing Accuracy (%) | ±0.25 | ±0.25 | ±0.25 | ±0.25 | ±0.25 |

Bitumen Weighing Accuracy (%) | ±0.25 | ±0.25 | ±0.25 | ±0.25 | ±0.25 |

Specification and Pictures of QLB series Compulsory Type Mobile Asphalt Plant

Model | QLB20 | QLB40 | QLB60 | QLB80 | QLB100 |

Production Capacity (T/h) | 20 | 40 | 60 | 80 | 100 |

Mixing Type | Batch | batch | Batch | batch | batch |

Dust Remove Effect (mg/Nm3) | ≤100 | ≤50 | ≤50 | ≤50 | ≤50 |

Fuel Consumption (kg/t) (Oil) | 5.5-7 | 5.5-7 | 5.5-7 | 5.5-7 | 5.5-7 |

Fuel Consumption (kg/t) (Coal) | 10-13 | 10-13 | 10-13 | 10-13 | 10-13 |

Aggregate Weighing Accuracy(%) | ±1.5 | ±1.5 | ±1.5 | ±1.5 | ±1.5 |

Bitumen Weighing Accuracy(%) | ±1 | ±1 | ±1 | ±1 | ±1 |

Total Power (kw) | 50 | 75 | 128 | 165 | 200 |

Specification and pictures of road repairing type mobile asphalt plant

Model | QLZ-3 | QLZ-6 |

Production capacity | 2-3 t/h | 4-6 t/h |

Capacity of drying and mixing drum | 1000kg | 2000kg |

Max. weight of recycled asphalt lump | Less than 2 kg | Less than 2kg |

Rotating speed of drying and mixing drum | 7-10 round/minute | 7-10 round/minute |

Heating time for one batch of material | 15 to 20 minutes | 20-30 minutes |

Discharging material temperature | 120-160℃ | 120-160℃ |

Fuel for heating | gas | gas |

Diesel engine power | 20HP | 12.7kw |

Diesel engine oil consumption | 230 g/hp.h | 244.8 g/kw.h |

Loading hopper capacity | 400kg | 700kg |

Overall size | 4580mm×2170mm×2470mm | 6034mm*3040mm*2350mm |

Total weight | 3t | 5t |

Main Component Pictures of Mobile Asphalt Plant

1) Aggregate batching machine

2) Drying drum

3) Dust filter

a. Cyclone dust filter

b. bag house dust filter

4) Finished product bin

5) Burner ( Depends on the fuel client uses, we can use oil burner, gas burner, coal burner, gas and oil burner, heavy oil and light oil burner etc.

a. Oil burner

b. gas burner

Welcome to contact us for details.